ACCESSORIES & OPTIMIZATION

CONVEYOR COMPONENTS

# 1 to 6 Not Visible

Made out of polyurethane material, its special shape makes it a fast and practical solution for minor alignement problems.

Made out of polyurethane material, its special shape makes it a fast and practical solution for minor alignement problems.

Rubber or polyurethane protection for chutes, to avoid build-up effect due to wet material.

Positioned at the head of the conveyor, allows effective cleaning of the belt, adapts to different types of applications and requires minimum maintenance.

Positioned at the head of the conveyor, allows effective cleaning of the belt, adapts to different types of applications and requires minimum maintenance.

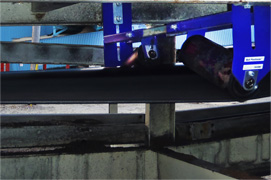

Rematech has many different systems that seal the loading point, which allows to contain dust and materiel inside the chute. It helps prevent and solve problems caused by overflows.

Rematech has many different systems that seal the loading point, which allows to contain dust and materiel inside the chute. It helps prevent and solve problems caused by overflows.

A very efficient solution for different belt alignment problems.

A very efficient solution for different belt alignment problems.

# 7 to 12 Not Visible

Protects the environment by reducing the dust and noise around the conveyor, and protects the belts against harsh atmospheric conditions.

Protects the environment by reducing the dust and noise around the conveyor, and protects the belts against harsh atmospheric conditions.

Supports the belt and the material conveyed during its travelling.

Supports the belt and the material conveyed during its travelling.

The head, tail or constraint pulleys allow training, alignment and tensioning of the belt. Dimensions and pulleys formats must be adequate to the conveyor system.

The head, tail or constraint pulleys allow training, alignment and tensioning of the belt. Dimensions and pulleys formats must be adequate to the conveyor system.

Rubber, polyurethane, ceramic or steel protection in the chutes, to reduce chute maintenance due to wear.

Rubber, polyurethane, ceramic or steel protection in the chutes, to reduce chute maintenance due to wear.

# 13 to 18 Not Visible

Positioned behind the primary scraper, allows belt cleaning optimization and adapts to different types of applications.

Positioned behind the primary scraper, allows belt cleaning optimization and adapts to different types of applications.

The UHMW surface allows the belt to slide easily, while the rubber allows impact absorption due to the material dropped on the belt. Ensures durability of the belt.

Provides belt support at the loading point. It consists of a steel structure and impact rollers or impact bars, protecting the belt against the impact load of the material transported on the belt. Ensures the durability of the belt.

Provides belt support at the loading point. It consists of a steel structure and impact rollers or impact bars, protecting the belt against the impact load of the material transported on the belt. Ensures the durability of the belt.

Maintains the belt in place on the return side.

Maintains the belt in place on the return side.

Provides belt and skirting support at the loading point. Its rubber lining absorbs the impact load caused by the material dropped on the belt. Ensures durability of the belt.

Provides belt and skirting support at the loading point. Its rubber lining absorbs the impact load caused by the material dropped on the belt. Ensures durability of the belt.

They secure the incoming angle near the pulleys and supporting rollers of the conveyor systems. They reduce the risk of injury. These protectors are in many cases necessary or required for workers safety.

# 19 to 24 Not Visible

Flex-seal skirt clamp systems adapt to every type of skirting allowing the skirt to be fixed effectively, to help reduce ajustment maintenance.

Flex-seal skirt clamp systems adapt to every type of skirting allowing the skirt to be fixed effectively, to help reduce ajustment maintenance.

Made of polyurethane, nylon, steel of cast iron, they are available in many different models and sizes, as required.

Specially developed for elevator belts, these mecanical fasterners are effective, safe and quickly installed.

Made of standard steel, stainless steel or galzanized steel, they are available in many different sizes and models, as required.

1 – Remtan guide rollers

2 – Chute lining efficient against material build-up

3 – Primary cleaner (scraper)

4 – Loading point sealing systems

5 – REMASKIRT premium skirting rubber

6 – Training idlers

7 – Conveyor hoods

8 – Rolling Idlers

9 – PHOENIX conveyor belt

10 – Pulleys

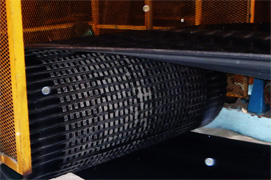

11 – REMAGRIP and Ceramic CK-X anti-skid pulley lagging

12 – Chute lining efficient against wear

13 – Secondary cleaner (scraper)

14 – Impact bars

15 – Impact beds

16 – Return rolls

17 – Impact rolls

18 – Pinch point protector

19 – Skirt clamp systems

20 – REMALINE anti-build up and anti-abrasion pulley lagging

Elevator belt components

21 – Elevator belting

22 – Elevator bucket

23 – Specialised fasteners

24 – Elevator bolts

Rematech distributes products from the following manufacturers:

RUBBERLOC: FAST PERMANENT REPAIR FOR CUTS & HOLES

Formulated and manufactured in the USA for unparalleled toughness and ease of use, Rubberloc is recognized around the world for its high performance and durability.

- Outstanding adhesion, durability and abrasion resistance dramatically increase conveyor belt service life

- RubberLoc can be used on longitudinal cuts, skid board abrasion zones and thru holes

- Unaffected by oil, grease and water, providing uncompromising solutions in the toughest environments

- Rapid cure time allowing for normal use of conveyor belt in as little as one hour.

- Easy surface prep and application

Rubberloc is a two-component, rapid cure system that can repair a wide range of wear, impact and tear damage, as these images show. Holes can be filled, tears repaired and edge damage restored – with minimum delay and cost. Each kit comes with all the essential components for a fast, permanent repair: Rubberloc material, surface cleaner, adhesion primer, application tool, stir stick and a full set of instructions. Enough to repair a 12″ by 4″ hole in a 3/4″ belt.